high speed double twisting machine

usage:

high speed double twisting machine used for bunching multi-strand copper wire, tined copper wire,aluminum wire, enamel wire, nickel-cladded wire, CCA, CCS and other wires.

machine featuers:

1. Royal machinery high speed double twisting machine with dynamic balance treatment, ensure stable and safe running at high speed.

2. Royal machinery high speed double twisting machine use heavy loading design, avoid shaking and noise at high speed running.

3. Royal machinery high speed double twisting machine use annealing treatment on whole machine structure, no deformation in long time use.

4. Royal machinery high speed double twisting machine use international famous brand key parts, reduce the failures in running.

5. Royal machinery high speed double twisting machine use different choice on the method of changing pitch, customer can choose changing gears, capstan wheels, or electrical setting.

6. Royal machinery high speed double twisting machine use different control system for choosing, PLC intelligent control system and button control system both avialable. customer can choose on their request.

technical parameter:

take up reel size: Max.Ø1000(OD)*750(W)

twisted wire cross section: 8-20mm2

twisted core wire diameter range: Max.12mm

single copper wire diameter: 0.72-1.50mm

single core wire diameter: 0.32-4.0mm

twist pitch range: 22.73-173.66mm

twisting direction: both S and Z direction

rotating speed: Max 800RPM, stepless adjustable.

main power: 22KW, inverter adjust speed

twist pitch change: gears / capstan wheels / electronic

reel lift: electrical

take up tension element: magnetic clutch / motor

electrical control system: PLC / buttons

operation interface: HMI/ buttons and switches

machine dimension: 3750×1860×1950mm

machine weight: 5400kg

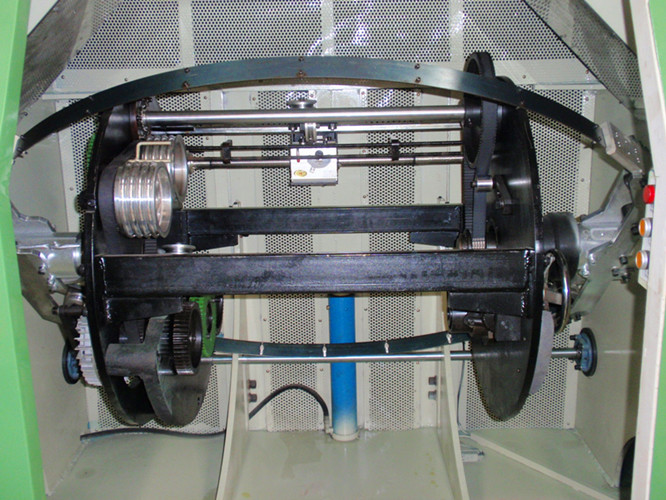

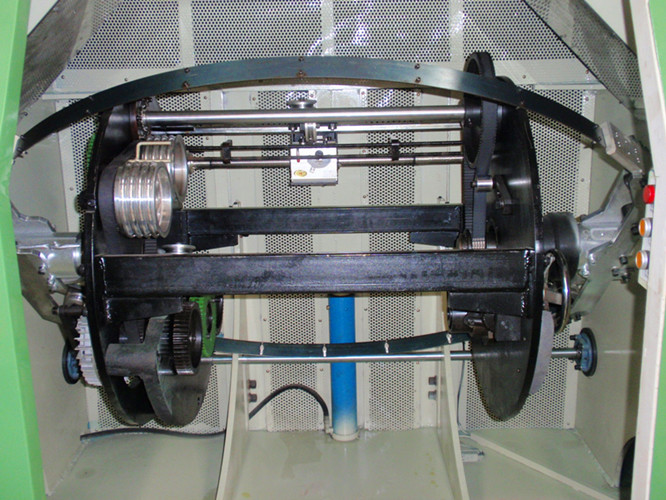

machine inner structure: