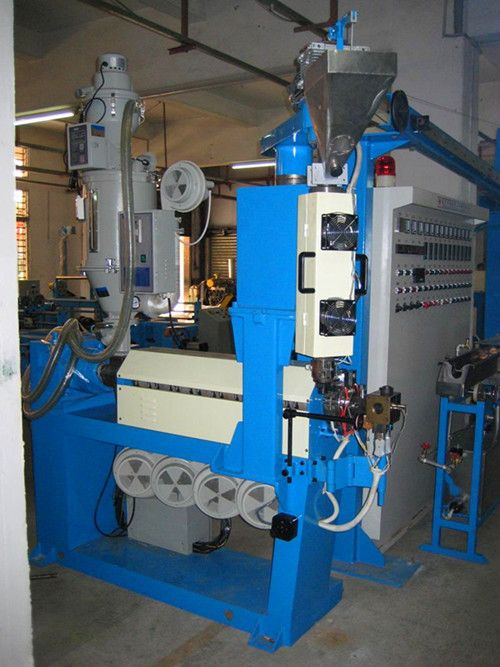

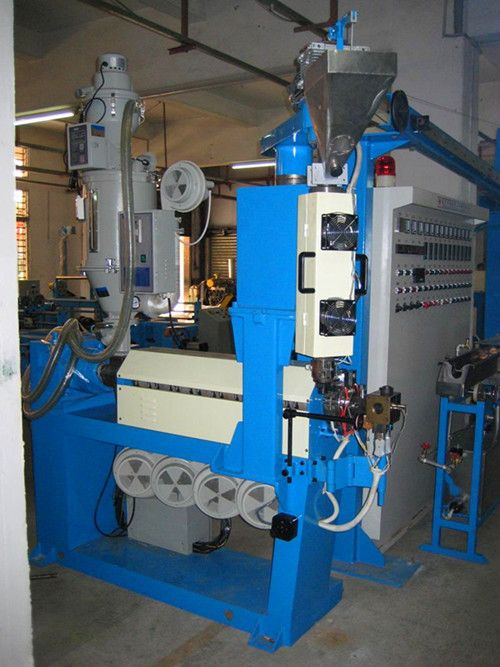

PVC LSZH HFFR TPE TPU cable insulation extrusion line

usage:

PVC LSZH HFFR TPE TPU cable insulation extrusion line used for data cable, power cable, Lan cable, electronic cable and other cables cable insulation extruding; PVC, PE, LSZH, PP, HFFR, TPR, TPU and other plastic all suitable to applicated on this line.

features:

1. Royal machinery PVC LSZH HFFR TPE TPU cable insulation extrusion line optimize screw design, better screw quality; machine have higher speed, insulation surface have better fineness, smoother and glosser

2. Royal machinery PVC LSZH HFFR TPE TPU cable insulation extrusion line concentricity around 93%-97%,diameter precision +/-0.005,diameter keep stable。

3. Royal machinery PVC LSZH HFFR TPE TPU cable insulation extrusion line use SCR POWER CONTROLLER, SSR, import high quality temp controller, temp control precision +/-1 degree.

4. Royal machinery PVC LSZH HFFR TPE TPU cable insulation extrusion line all process use PLC control, industrial control system and remote control system is optional, all production process all easy to monitor and control.

parameter:

suitable cable: power cable, control cable, data cable, high frequency cable, electronic cable insulation extruding.

Extrusion material: PVC, PE,LSZH, HFFR, XLPE, PP, TPE, TPU

extruding output: 90kg/h, when the crosshead open.

Conductor dia.: Ф1.5~5.0mm

output dia.:Ф2.0~6.0mm

dia. precision: +/-0.002

line speed: Max.300m/min

L/D of screw: 26:1

compression rate: PVC:2.6-2.9; PE:2.9-3.4;

concentricity: 90%-93%, according to the extruding die design and conductor quality.

temp controller: ±1℃

center height: 1000mm, or customized

total length: within 20m

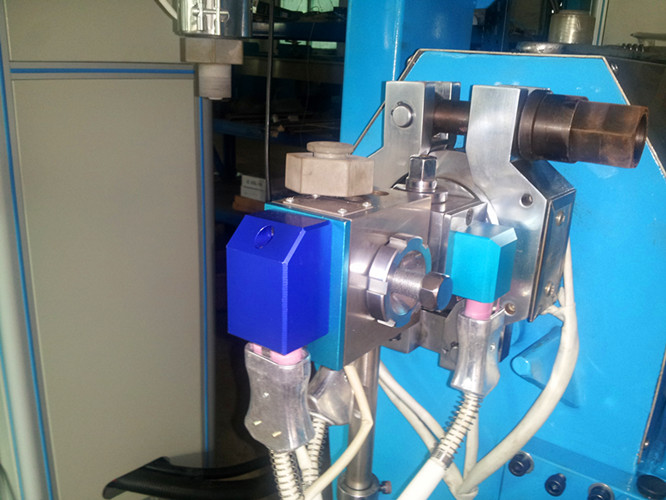

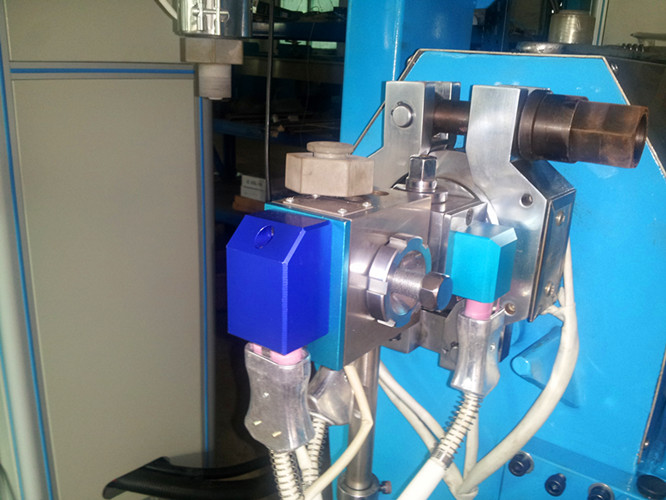

main extruder and crosshead: