fine wire vertical wire wrapping machine

usage:

fine wire vertical wire wrapping machine used for super fine core wire tape wrapping, such as signal cable, communication cable, magnet wires and other cables. the wrapping material can be aluminum foil, copper foil, PTFE, PET, and other materials.

machine featuers:

1. Royal Machinery fine wire vertical tape wrapping machine is a high speed machine, the wrapping machine max speed can reach 2500RPM, is 2 times of general one.

2. Royal Machinery fine wire vertical tape wrapping machine with the intelligent functions like tape break, wire break machine auto stop, tape finish machine auto stop, with wire backward function, greatly reduce raw material cost and labour cost.

3. Royal Machinery fine wire vertical tape wrapping machine use electrical taping lay length, lay length set on HMI, PLC auto calculated, precision within 2.5%.

4. Royal Machinery fine wire vertical tape wrapping machine adopt constant tension control system,tape tension auto trace, keep constant from full reel to empty reel.

4. Royal machinery fine wire tape wrapping machine has different designs for choosing: pad type/spooler wrapping head as option, vertical/horizontal machine type as option,on-line sintering as option, one line diameter and spark testing as option,one layer, two layer, three layer and more layers wrapping as option.

technical parameter:

suitable cable: signal cable, communication cable, magnetic wires fine core wires tape wrapping.

suitable material: Aluminum foil, copper foil, PET, PTFE

inlet wire dia.: Ф0.2~1.0mm

outlet wire dia.: Ф0.25~1.20mm

rotating speed: Max 2500RPM

tape size: OD: Max.Φ100; ID:2″ or 3″(56 or 75mm); height: <100mm; width: 2~6mm; thinckness: 0.01~0.08mm; weight<1KG

wrapping lay length: 3~10mm; overlapping rate 0~67%; set on PLC; precision ±1%

wrapping direction: S, Z both

wire thread tube: >Φ5mm

tension control: magnetic clutch/ hysteresis clutch/servo motor

tension range: 10-100g, precision within 2%

tape storage: longer than 240mm

door control: when door open, machine can not start

wire break: machine auto alarm and stop

tape break: machine auto alarm and stop

tape finish: machine auto alarm and stop

taping die: taping inner die inside the center taping tube, wire holding die is located on the tape store rod, the dies can move back and forth.

drive motor: 0.75KW servo motor with controller

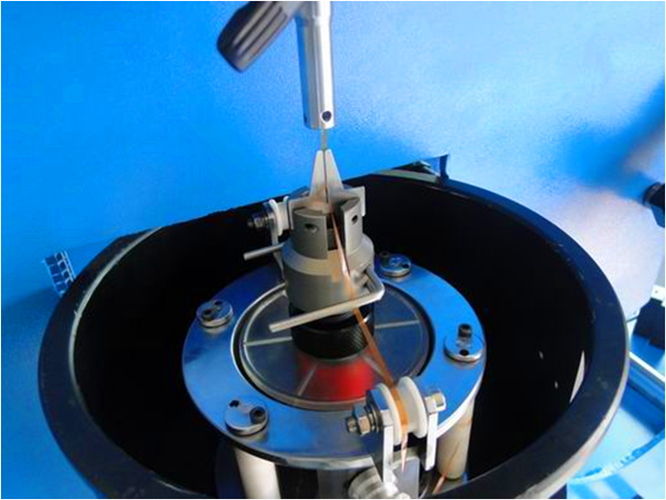

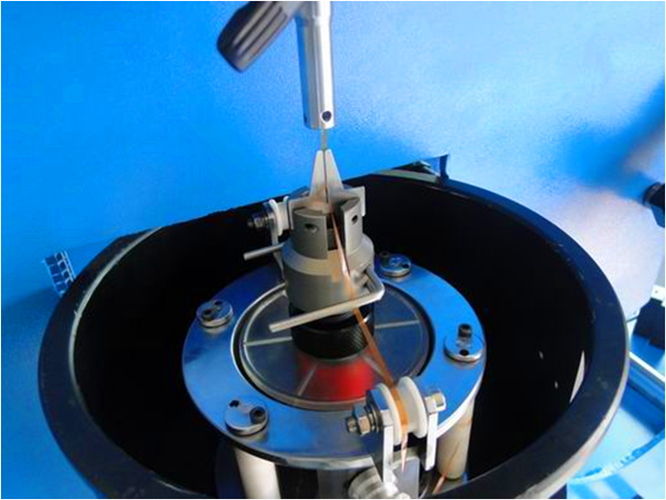

machine inner structure: