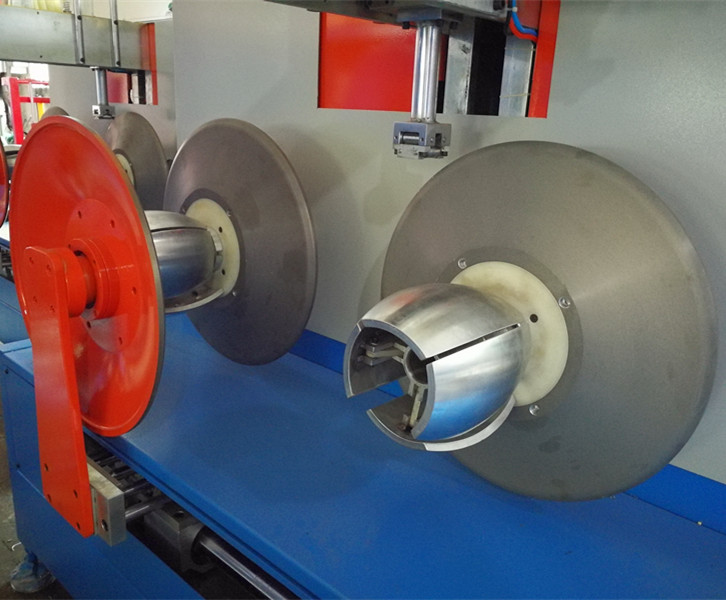

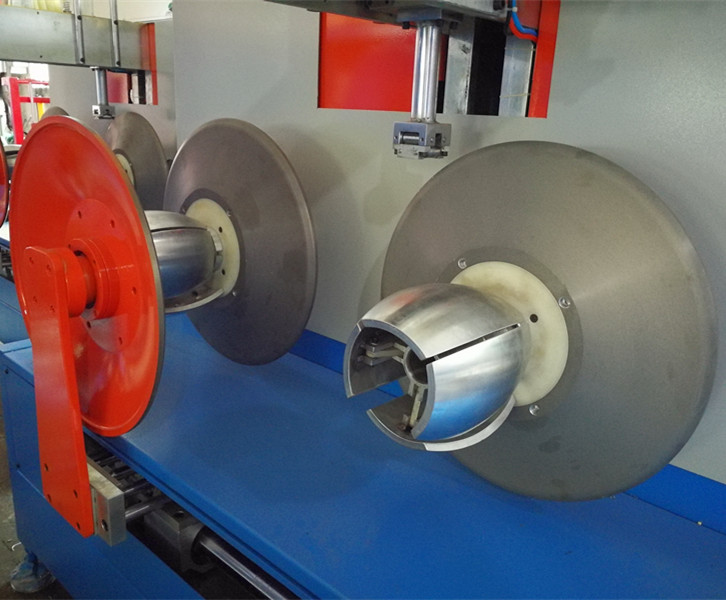

PLC Lan cable cross coiling machine

usage:

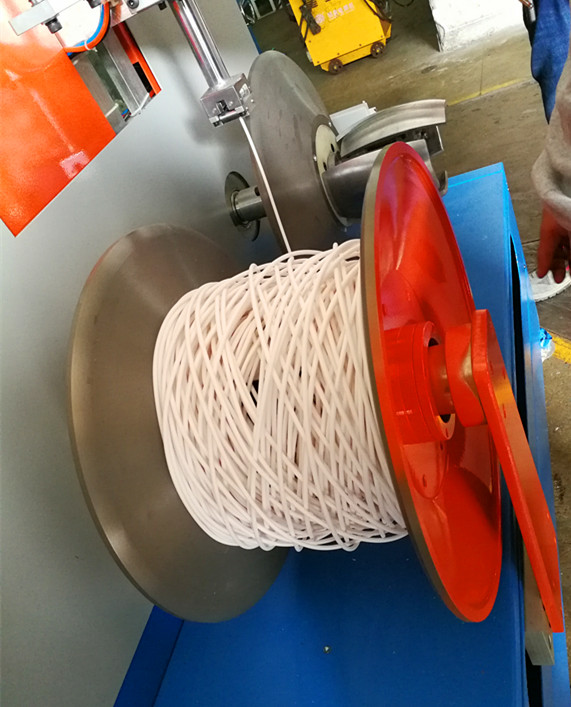

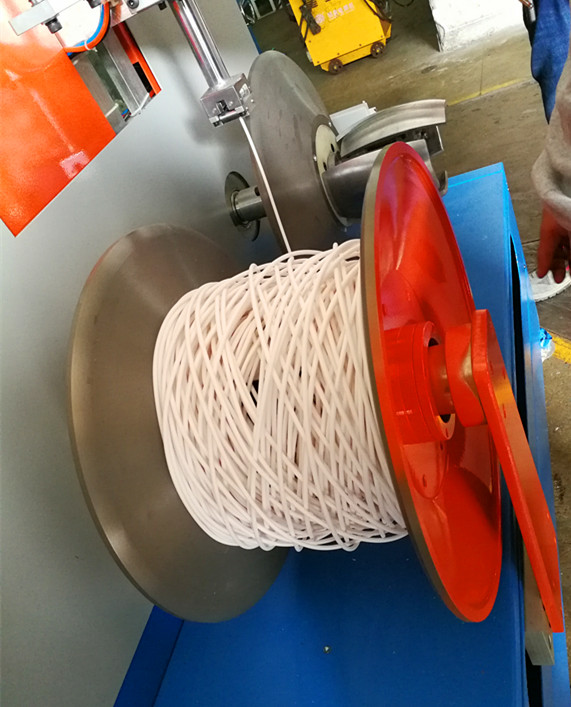

Lan cable cross cable coiling machine used for Lan cable or CATV cable cross coiling; tangle-free cable coiling, left an center hole to take out the cable from package box.

technical parameter:

coiling type: Cross coiling, dual shaft coiling

Max RPM: Max.250 RPM

cable coil size: OD Max. ψ400mm ×ID ψ180mm﹙cambered surface average﹚×width Max. 250mm

coiling control: 2 sets 1000W servo motor with gear motor

traverse control: 1000W servo motor with gear motor

traverse: Crank structure, linked with coiling speed.

length counting: Precise Encoder counting

tighten way: Quick tighten way

electrical control: Siemens PLC

machine inner structure: