small size semi-automatic cable coiling machine

usage:

small size semi-automatic cable coiling machine used for power cable, control cable, instrument cable, parallel cable, and other cables auto coiling; cable coiling machine has big cable coiling size range, easy to operate, lower machine price.

technical parameter:

machine model: small size

cross section range: 0.5-6.0mm2

Max. RPM: 700RPM

traverse: Double die traverse

cable coil ID: 120mm

cable coil OD: 300mm

cable coil height: 40-100mm

tighten rope: 2

drive power: 2.2KW

traverse type: semi-auto cable coiling machine use auto traverse tension, traverse performance not influenced by cable size, neat traverse, tight cable coil.

reel load: semi-auto cable coiling machine use auto shaft tighten, quick load and unload.

control type: cable coiling machine use Inverter control, with auto break function.

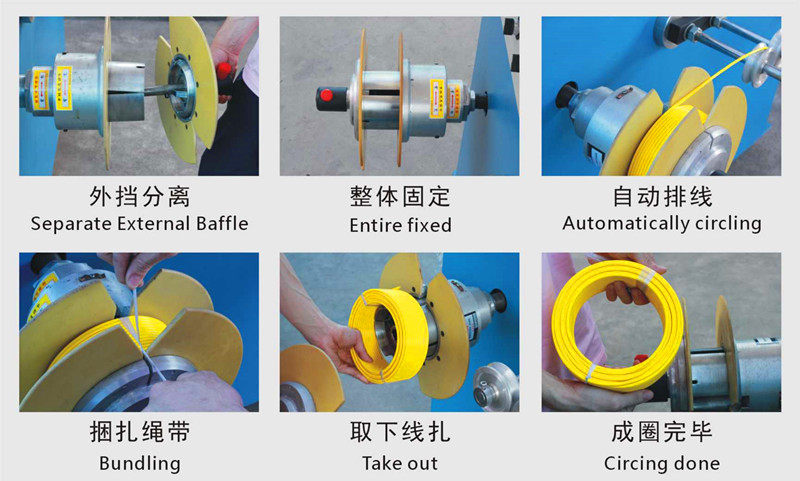

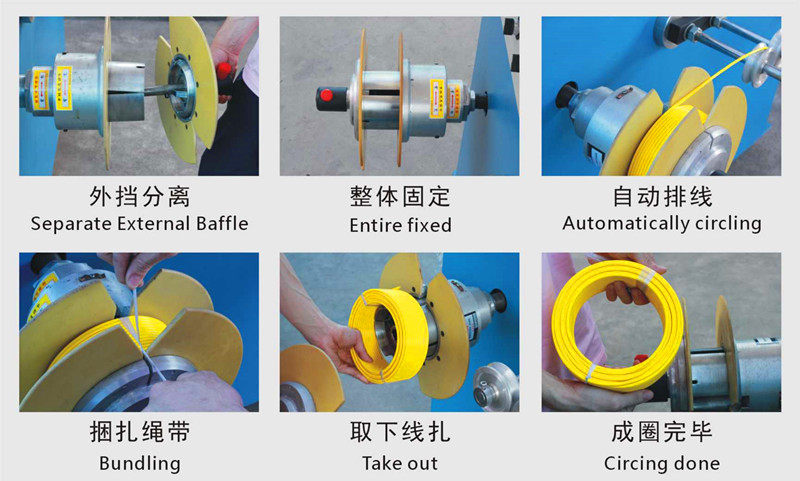

machine operation: