QT500 quadruple twisting machine

usage:

quadruple twinning machine used for Lan cable( cat5, cat5e, cat6, cat6e,cat6a, cat7), instrument cable, control cable or other cables two core wires pair twisting, twinning. back twist rate can be set on HMI 0-100%. the twisting bow running one circle, get four twist pitch, when running at the same RPM, triple twist line speed is 2 times of double twister, 4 times of single twister.

features:

1. Royal machinery quadruple twinning machine use quadruple twisting pitch, when back twist rate at 25%, line speed is 2 times of the double twist.

2. Royal machinery quadruple twinning machine use heave loading design, avoid shaking and noise at high speed running.

3. Royal machinery quadruple twinning machine use servo motor electrical twist pitch, set pitch on HMI, PLC control, precision+/-2%。

4. Royal machinery quadruple twinning machine use motor controlled take up tension, tension keep consist from empty reel to full reel.

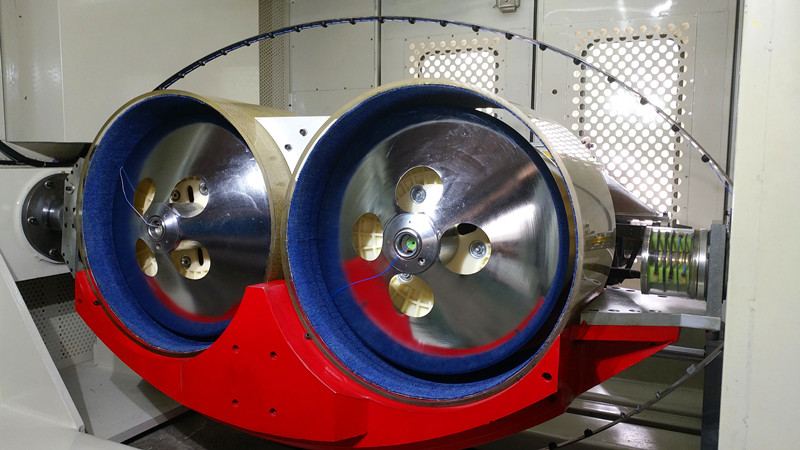

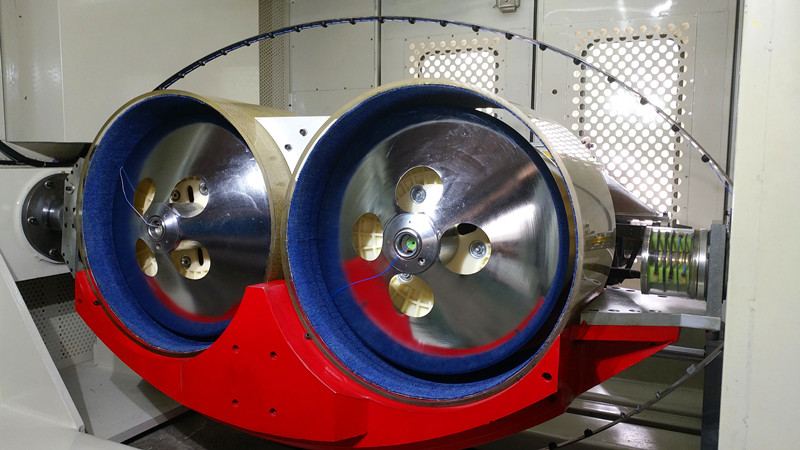

Back twister:

rotate speed: Max.1800RPM

bow material: 65Mn spring steel

twist pitch: 5~50mm

reel size: 500mm

core wire diameter: Ф0.8~1.7mm

pay off tension: counter weight type, through adding weight blocks to adjust the pay off tension, tension range 0.6-3.0kg(adjustable)

tension wheel dia.: φ110

reel lift: Power driven hydraulic lifting

reel tighten: Spring auto tighten, pneumatic unlock

brake: magnetic brake

bearing weight: MAX150kg

pay off motor: 7.5KW servo motor +speed controller

bow driven motor: 7.5KW servo motor +speed controller

flyer barrel: High strength, high hardness, wearproof, transparent acryl barrel

back twister features:

1. uniform cores: traditional back twister, the two core wires consumes different tension when getting through the twisting bow, which makes difference on the core wire physical length, return loss such as crosstalk, far-end crosstalk, time delay; quadruple twinning machine use flyer type zero tension pay off, pitch finish before getting into the twisting bow, which have less effect on uniformity of core wires.

2. durable design: quadruple twinning machine use dynamic balancing treatment, low noise and steady; hard materials makes the machine durable.

3. stable tension control: zero tension pay off with single back twisting and without going through the bow, remains stable tension when machine start/stop/running.

4. easy operation: quadruple twinning machine with functions: PLC control system, HMI operation system, spring auto tighten reel, pneumatic loose reel, and electrical lift reel

Capstan

a. structure: vertical type

b. core wire diameter: 1.0~4.0mm

c. Line speed: 250m/min, subject to wire diameter.

d. Capstan pulley: 4-6 grooves, ∮237.1, Aluminum Magnesium alloy, rubber covering surface.

e. Drive: 1.1KW servo motor with driver

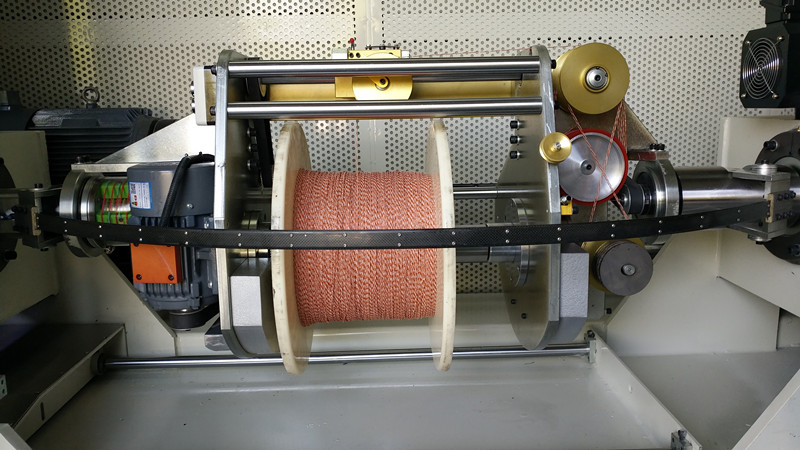

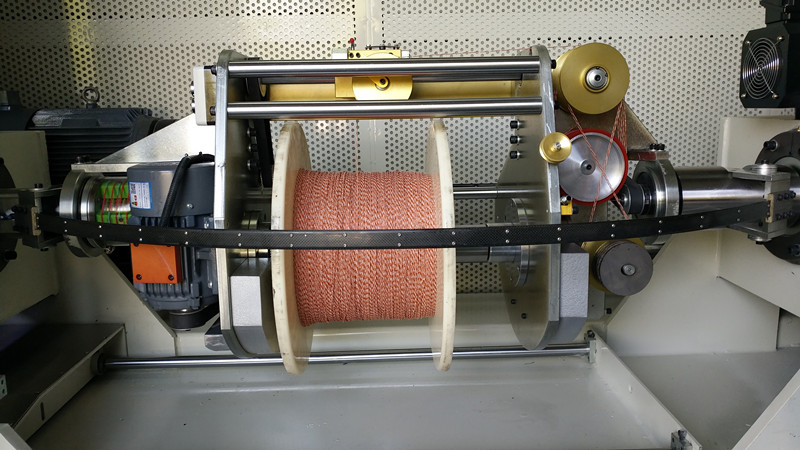

twinner:

structure: Double twist stable tension pair twisting machine

rotate speed: MAX1800rpm

bow material: 65Mn spring steel

twist pitch: 5~50mm

reel size: 500mm

core wire diameter: Ф0.8~1.7mm

pay off tension: counter weight type, through adding weight blocks and balancing weight to adjust tension, tension range 0.6~3kg(adjustable).

tension wheel dia.: φ110

reel lift: Power driven hydraulic lifting

reel tighten: Spring auto tighten, pneumatic unlock

brake: magnetic brake

bearing weight: MAX150kg

take up motor: 1.1KW servo motor +speed controller

bow driven motor: 7.5KW servo motor +speed controller

traverse: φ30 polish traverse

twinner features:

1. stable tension: compare with traditional pair twisting machine, quadruple twinning machine adopt motor active take up, via changing balance weight to adjust take up tension, remain stable tension from empty to full reel.

2. precise pitch: quadruple twinning machine use PLC direction control twisting pitch, easy to change pitch.

3. easy operation: quadruple twinning machine has close passage for wire getting through, special design with easy operation

4. less bending: quadruple twinning machine large capstan wheel and pulleys, less bending on wire materials, less damage on pitch.

5. easy unloading: quadruple twinning machine slide board type unloading bobbin, no need manual lifting, easy to unload the bobbin

6. low noise: quadruple twinning machine use double layer homeycomb structure, low noise will be generated, electronic door locking, save for operator.

Control system:

A. Weilun 5.7 inch touch screen, Siemens PLC

B.Control switches, button, indicator lamps(CHINT), contactors,air switches(SHIHLIN), relays(OMRON)

C.AC Motors made by Futian, Gear Motor made by Tunglee, Frequency Inverter made by Inovance.

machine inner structure: